| |

| All the steps : |

| |

| 1.- With a Olfa knife make a line

every half inch to help you remove the copper. |

| |

|

|

| |

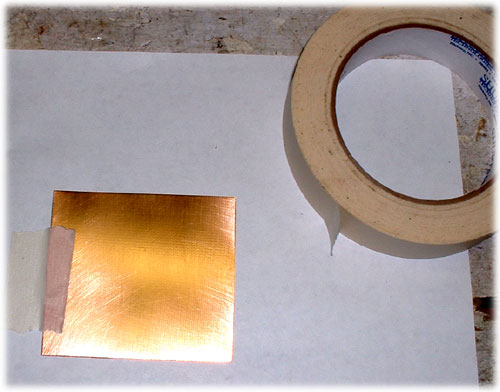

| 2.- Cut and clean to proper size. |

| |

|

|

| |

| 3.- Clean with Acetone. |

| |

|

|

| |

| 4.- Make sure that you dont touch

the copper side... Use masking tape to hold the PCB. |

| |

|

|

| |

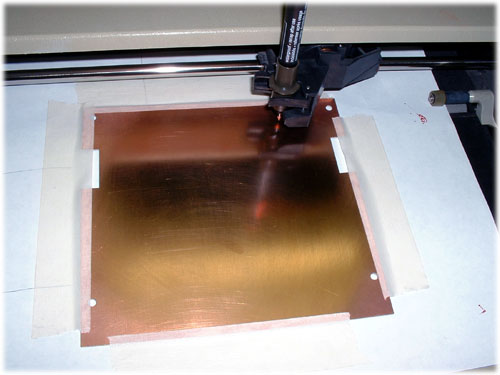

| 5.- The Plotter is writing the

schematic. |

| |

|

|

| |

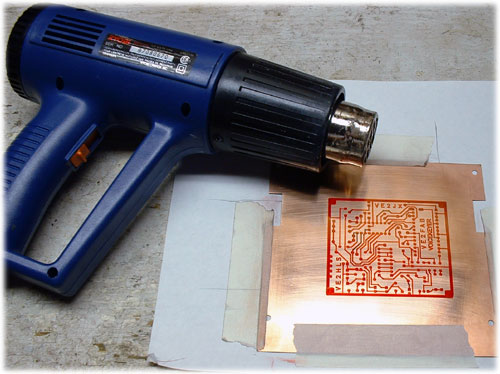

| 6.- Dry the ink with a heating gun

for 30 to 35 seconds. |

|

|

| |

7.- Put

250 grams of Persulfate d’ammonium for 1 litre of water, heat to 100 degres

celcius.

Use tweeser to move the PCB.

Put the PCB face down 1/8" from the bottom, slowley move the

water, after a wile the copper start to be remove, 5 ŕ 10 minutes

will be enought, after 12 minutes change the Persulfate. |

| |

| Here are all the steps. |