|

|

Hy-Gain TAILTWISTER rotor cleaning and greasing |

|

and Brak-D-Lay option installation |

|

|

|

Hy Gain TAILTWISTER |

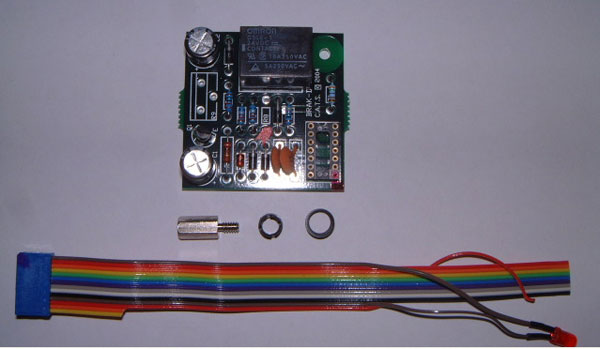

| If you are installing a second hand rotor in your antenna farm, it will take you a few moments to clean and grease it. Here is the job we did at our radio club rotor. We also applied the Brak-D-Lay option that provides 5 seconds delay for the brake system on HAM rotators. |